Fitting radial pin tumbler locks

Body nut / mounting nut

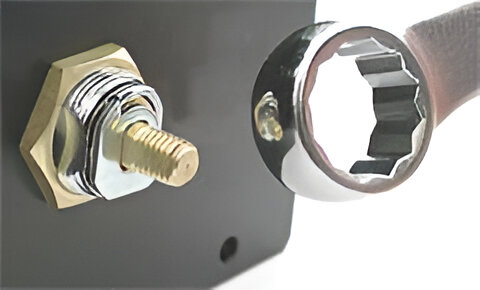

The lock should be positioned in the application, together with any mounting washer, protective collar or spacer, and the body nut screwed on, making sure the nut turns freely and is not cross-threaded. The body nut should be tightened until the lock is held securely.

Tail nut

Take care not to over-tighten the tail nut or screw, as excessive tightening may lead to stiff lock movement or even to the lock seizing. For most of the tail nuts and screws that we supply, we recommend these are screwed until tight and then turned one-tenth of a turn further. Where a low torque wrench is available, a tightening force of between 2Nm and 3Nm is recommended. If you are fitting your own tail nut or assembly, a torque tightening force outside this range may be appropriate.

Any locking mechanism fitted to the tail-piece of the lock should move freely and should not impart a force onto the lock. For example, do not use a spring return mechanism, unless you talk to us first.

Lubrication

Silicone based or aerosol penetrating lubricants may be used sparingly. Do not lubricate the lock with heavy oil, as this will trap any dirt or dust that may enter the lock, causing excessive wear.

Keys

Avoid keys becoming damaged as this may both prevent the lock operating correctly and damage the lock mechanism. Should the key be reluctant to turn in the lock, do not apply excessive force to the key bow, eg. by using tools to attempt to turn the lock. Investigate the problem and if you are unable to identify the cause, contact us on +1 860-378-0302 or e-mail usasales@camlock.com

Further assistance

Should you experience difficulties with installing a lock, please contact us on +1 860-378-0302 or e-mail usasales@camlock.com